The Automobile Engineering Lab (PME 717) provides practical exposure to the fundamental systems of modern vehicles, enabling students to bridge theoretical knowledge with hands-on experience. The lab focuses on the study, demonstration, dismantling, and assembly of critical automobile components. Students perform experiments on braking, ignition, and fuel supply systems for both SI and CI engines, along with gearboxes, steering mechanisms, and suspension systems. Cooling, lubrication, lighting, and starting systems are also explored, ensuring a comprehensive understanding of vehicle operation. Advanced topics include the study of MPFI and fuel injection systems, universal joints, propeller shafts, and differentials. Beyond demonstration, students are encouraged to design innovative lubrication and ignition systems with emphasis on modern features and environmental considerations. By completing a minimum of twelve structured experiments, learners develop diagnostic skills, technical competence, and problem-solving abilities essential for real-world automotive applications. This lab builds practical expertise to complement core automobile engineering knowledge.

- Teacher: RAKESH CHANDMAL Sharma

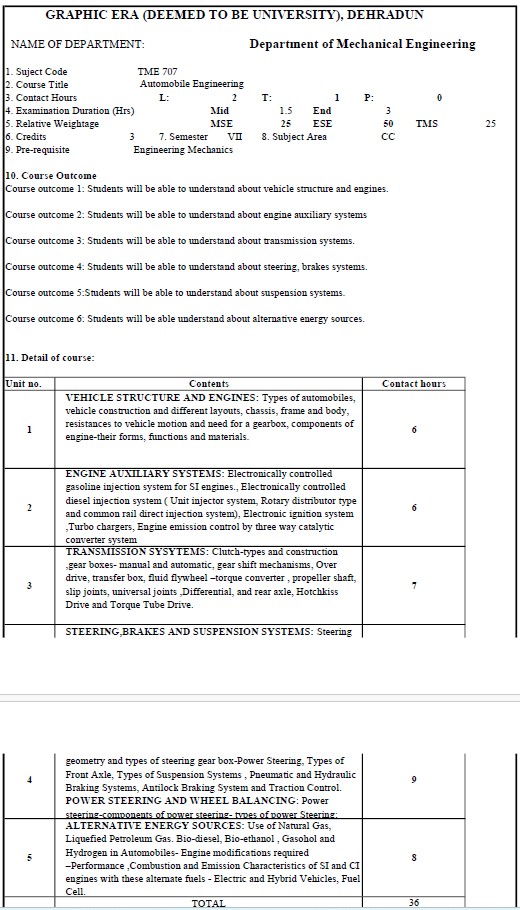

The course Automobile Engineering (TME 707) provides an in-depth understanding of modern vehicle systems, covering fundamental design, operation, and technological advancements. It begins with vehicle structures, chassis, body design, and engine components, emphasizing their materials, forms, and functions. Engine auxiliary systems such as electronically controlled fuel injection, ignition, turbocharging, and emission control mechanisms are studied to address efficiency and environmental concerns. Transmission systems including clutches, gearboxes (manual/automatic), torque converters, differentials, and drives are explored for their role in power delivery. The course also focuses on steering geometry, types of steering gear, suspension systems, braking technologies including ABS and traction control, and wheel balancing for safe handling and comfort. Furthermore, students learn about alternative energy sources such as CNG, LPG, biodiesel, ethanol blends, hydrogen, electric, hybrid, and fuel cell vehicles. By completion, students gain a comprehensive knowledge of conventional and advanced automobile systems, preparing them for modern challenges in automotive engineering.

- Teacher: RAKESH CHANDMAL Sharma

CO1: Recall the fundamental concepts and components of industrial automation systems including sensors, actuators, control structures, and communication protocols.

CO2: Explain the working principles of various sensors, transducers, and signal conditioning techniques used in measurement and automation..

CO3: Demonstrate the implementation of PID controllers and sequence control logic using PLCs in basic industrial automation problems

CO4: Analyze the performance of control systems using tuning methods and advanced control strategies like feedforward, cascade, and predictive control.

CO5: Evaluate the effectiveness of actuator systems and electric drives in terms of efficiency, responsiveness, and energy savings for automation tasks.

CO6: Design a simple automation system integrating sensors, controllers, actuators, and communication interfaces for a real-time industrial application.

- Teacher: DURGESHWAR PRATAP Singh

Course Outcome 1: To understand and learn about industrial robot and its components and its

use

Course Outcome 2: To learn about different operating modes a perform Jogging operation

Course Outcome 3: To define Tool and Base in robot

Course Outcome 4: To learn and make programming for robot

- Teacher: DURGESHWAR PRATAP Singh

|

INTRODUCTION: Definition of Quality, Dimensions of Quality, Quality costs -, Basic concepts of Total Quality Management, Historical Review, Principles of TQM, Wheels of TQM, Benefits of TQM, Scope of TQM, Types of customers, Barriers to TQM Implementation. One relevant case study. |

|

TQM PHILOSOPHIES and PRINCIPLES: Quality Management Philosophies: Deming Philosophy, Juran Philosophy, Juran trilogy, Taguchi and his quality loss function, Crosby and quality is free, PDCA and PDSA Cycle, 5S, Kaizen, Customer Perception of Quality, Customer Complaints, Service Quality, Customer Retention, Employee Involvement - Motivation, Empowerment and performance appraisal One relevant case study. |

|

STATISTICAL PROCESS CONTROL (SPC) and RELIABILITY: The seven tools of quality, Statistical Fundamentals - Measures of central Tendency and Dispersion, Population and Sample, Normal Curve, Control Charts for variables and attributes, Process capability, Software used in SPC, Concept of six sigma, Lean manufacturing., lean six sigma , use of software for project management Reliability definition, bathtub curve, failure rates, hazard function derivation for exponential probability distribution. Reliabilty in series and parallel, system reliability. Introduction to R software One relevant case study using R. |

|

TQM TOOLS: Benchmarking - Reasons to Benchmark, Benchmarking Process, Quality Function Deployment (QFD) - House of Quality, QFD Process, Benefits, maintenance breakdown maintenance, prevention maintenance, Total Productive Maintenance (TPM) - Concept, Improvement Needs, FMEA - Stages of FMEA. One relevant case study using free software for QFD an FMEA, Poka-Yoke. |

|

QUALITY SYSTEMS: Need

for ISO 9000 and Other Quality Systems, ISO 9000:2000 Quality System -

Elements, Implementation of Quality System, Documentation, Quality Auditing,

TS 16949, ISO 14000 - Concept, Requirements and Benefits. BIS Introduction

and types of standards, TPS, DIN |

- Teacher: LALIT RANAKOTI